EX-Fusion Inc.

Tokyo Institute of Technology

EX-Fusion Inc. (CEO: Kazuki Matsuo, hereinafter referred to as “EX-Fusion”) has established a Collaborative Research Cluster focused on advancing liquid metal devices (Terminology 1) for the realization of commercial laser fusion reactors (Figure, Terminology 2) in collaboration with Tokyo Institute of Technology (President: Kazuya Masu, hereinafter referred to as “Tokyo Tech”). The signing ceremony to formalize this partnership was held on October 11, marking the official commencement of their joint efforts.

Photograph: The signing ceremony

The ‘EX-Fusion Liquid Metal Collaborative Research Cluster’ has been established with the support of the Tokyo Tech’s Open Innovation Platform. It aims to provide support for research management, intellectual property strategy, and commercialization, with the ultimate goal of facilitating the societal implementation of research outcomes developed at the Collaborative Research Cluster.”

- Background & Objectives

In the midst of the urgent demand for energy supplies that do not emit greenhouse gases, laser fusion reactors are globally garnering high expectations as a sustainable energy source. Nuclear fusion reactions are one of the natural phenomena through which the sun, like all other stars, generates immense energy, involving the fusion of atomic nuclei, such as hydrogen, under high-temperature and high-pressure conditions, transforming them into heavier nuclei like helium. Laser fusion, on the other hand, is a technology that induces nuclear fusion reactions by irradiating fuel with lasers, resulting in the generation of energy. Leveraging seawater resources, it offers a safe and sustainable energy supply option. Furthermore, it possesses the ability to flexibly adapt to fluctuations in electricity demand, and over the long term, it is projected to be a key player in the drive towards decarbonization. However, while numerous research and development efforts are underway worldwide to address technical challenges and enhance energy efficiency, as of the present, commercial laser fusion reactors have not yet been realized.

Through collaborative research between EX-Fusion, which develops laser fusion reactors, and Tokyo Tech, which conducts academic research related to liquid metal fluid, the Collaborative Research Cluster aims to construct a concept for liquid fuel blankets suitable for laser fusion reactors. It will also develop the necessary liquid blanket component technologies while working broadly on joint research towards designing a blanket mock-up loop (Terminology 3). The insights and liquid metal technology group gained from this collaborative research are expected to be useful not only in fusion but also in a wide range of fields such as liquid metal mirrors and environmental purification technologies. EX-Fusion is a startup company developing essential technologies for laser fusion reactors, including lasers and fuel targets. It has been recognized by Toyo Keizai, a major Japanese economic magazine, as one of the ‘Top 100 Outstanding Ventures’ in 2023. Through collaboration between EX-Fusion and Tokyo Tech, which is at the forefront of research on energy conversion systems using liquid metal fluid, they plan to jointly tackle such a wide range of technological applications, aiming to maximize the social implementation of these technologies.

- Collaborative Research Themes

Advanced Research on Liquid Metal Devices for the Realization of Commercial Laser Fusion Reactors

- Details of Collaborative Research

The Collaborative Research Cluster will enhance the large-scale synthesis technology of high-purity liquid lithium-lead breeding material (Terminology4), which is essential for commercial reactor operation, leveraging the technical expertise accumulated by Tokyo Tech. It will also develop the final optical system (Terminology 5) of the laser irradiation system applying liquid metal technology. By integrating these technologies, the Collaborative Research Cluster will design a blanket mock-up loop. Furthermore, it will also consider applying the liquid metal technology developed through this collaborative research to Low-melting-point metal mirrors for deep space exploration (Terminology 6) and environmental purification technologies such as seawater desalination. By collaborating, EX-Fusion, which is developing laser and fuel target technologies for laser fusion reactor development, and Tokyo Tech, which is conducting research on energy conversion systems using liquid metal fluid, aim to accelerate the early realization of laser fusion energy.

- Overview

Name: EX-Fusion Liquid Metal Collaborative Research Cluster

Location: Ookayama Campus, North Building 2, Room 274

Duration: October 1, 2023, to September 30, 2026

Research Team:

Masatoshi Kondo (Institute of Innovative Research, Associate Professor) –Cluster Director

Kazuki Matsuo (EX-Fusion Corporation, President and CEO) –Associate Cluster Director

Yoshitaka Mori (EX-Fusion Corporation, Chief Technology Officer)

Research Responsibilities:

Tokyo Tech: Development of liquid metal blankets for laser fusion reactors and consideration of the application of liquid metal technology to environmental purification

EX-Fusion: Comprehensive conceptual design of the entire laser fusion reactor and specification formulation for chamber and optical systems- Research Topics:

- Research and development concerning the concept of liquid fuel breeding blankets for laser fusion reactors

- Research and development on high-purity synthesis technology for liquid fuel breeding material for laser fusion reactors

- Research and development on the final optical system for laser fusion reactors

- Research and development on environmental purification technologies utilizing liquid metal technology

- Future Plans

Over the next three years, the Collaborative Research Cluster aims to advance the high-purity synthesis method for liquid fuel breeding material, which is key to the fuel cycle of laser fusion. This technology development aims to support fusion energy development happening globally. In addition, while conceptualizing the liquid blanket system, they will develop various technologies related to its longevity and operational efficiency. By integrating these blanket technologies into the laser fusion reactors developed by EX-Fusion, they aim for the commercialization of laser fusion energy within the next 10 years.

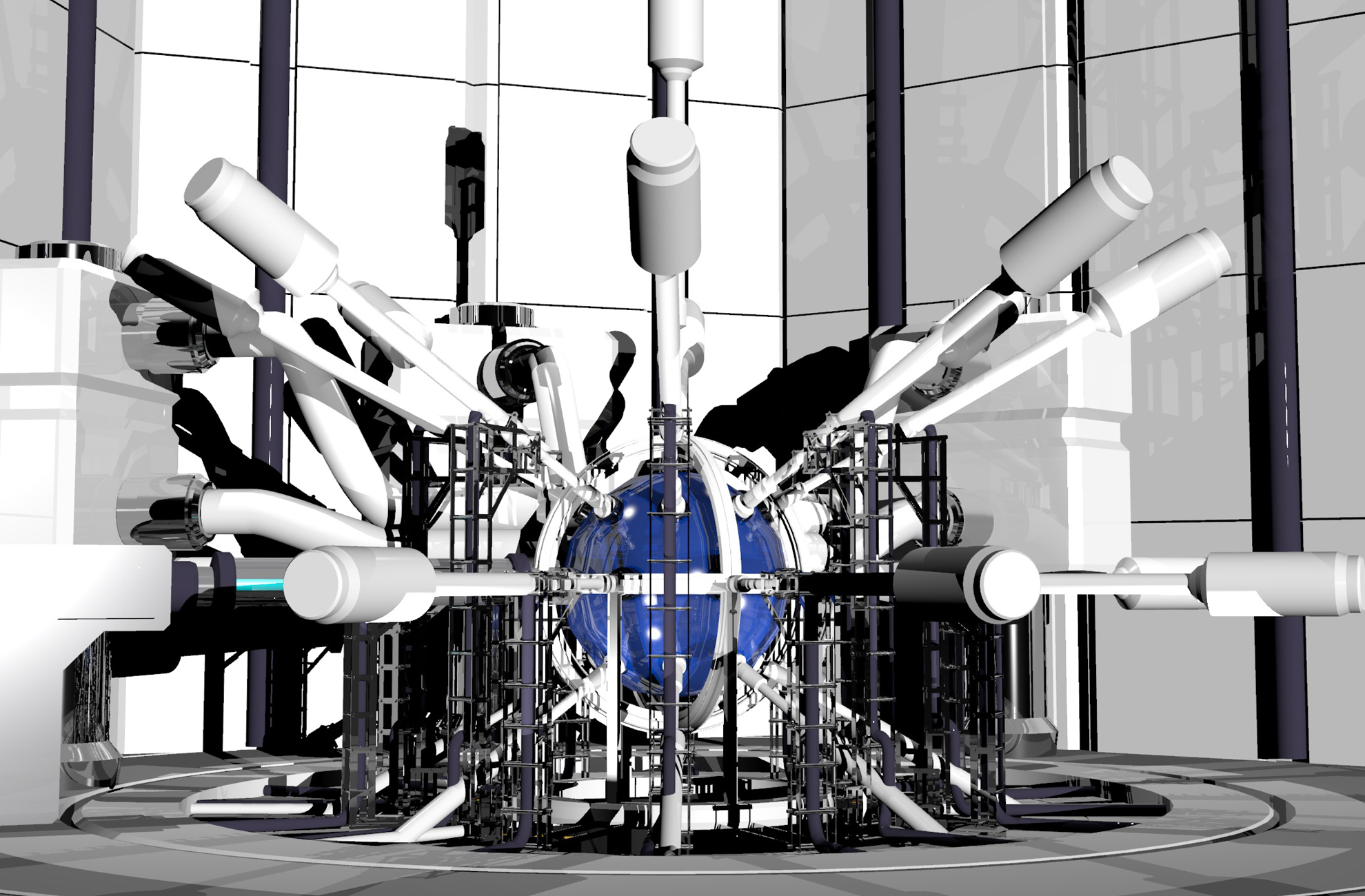

Figure: Conceptual Design of the Commercial Laser Fusion Reactor

【Terminologies】

- Liquid Metal Devices: These refer to components such as the liquid lithium-lead (LiPb) blanket responsible for fuel breeding and energy conversion in a laser fusion reactor, liquid metal walls that protect structural materials, and liquid metal mirrors with excellent damage resistance for laser irradiation. By irradiating the flowing liquid lithium-lead alloy (LiPb) with neutrons produced during nuclear fusion reactions, it produces fuel, such as tritium, and thermal energy.

- Commercial Laser Fusion Reactor: A clean energy source that is safe, reliable, and does not produce high-level radioactive waste. It is generated by a compact fusion reactor that uses abundant fuel extracted from seawater. It has the same or higher power output as a nuclear reactor while maintaining the safety levels of conventional renewable energy. The system can also adjust to load variations by changing the repetition rate of the laser.

- Blanket mock-up loop: The experimental apparatus for the continuous extraction of energy while circulating liquid metal, serving as the liquid fuel breeding blanket for a laser fusion reactor

- Liquid Lithium-Lead Fuel Breeding Material: A liquid alloy of lead and lithium, it functions both as a neutron multiplier and as a tritium breeder. A liquid metal has an excellent heat transfer property as a coolant, since it works as a fluid of molten metal. Tokyo Tech successfully developed a low-pressure synthesis method using a potato masher-type stirrer in 2022 and published a paper on it the same year.

Figure: Liquid metal

【Paper Information】- Journal: Corrosion Science

- Title: Corrosion-resistant materials for liquid LiPb fusion blanket in elevated temperature operation

- Authors: Masatoshi Kondo, Susumu Hatakeyama, Naoko Oono, Takashi Nozawa

- DOI:10.1016/j.corsci.2021.110070

- Final Optical System: The mirrors, which is called the final optical system, which are essential for reflecting the laser onto the fuel target and required for irradiating the fuel target with a laser, are exposed to high-energy neutrons. Therefore, there is a need for a final optical system that can rapidly recover from neutron-induced damage. In this joint research, studies on self-healing functionality leveraging the melting and solidification of low-melting-point metals are planned.

- Low-melting-point metal mirrors for deep space exploration: Tokyo Tech has introduced a concept for simplifying the transportation and installation of metals, such as liquids, to create primary telescope mirrors on celestial bodies like the moon. Fundamental results regarding this concept were published in a paper in 2023.

【Paper Information】- Journal:Results in Optics

- Title:Fundamental study on optical performance of low-melting-point metal mirrors for space telescopes

- Authors:Eisuke Imaizumi, Masatoshi Kondo, Katsuya Murakami, Yutaka Hayano, Yuichi Matsuda,

- DOI:10.1016/j.rio.2023.100473